Predictable and repetitive behavior in hardening

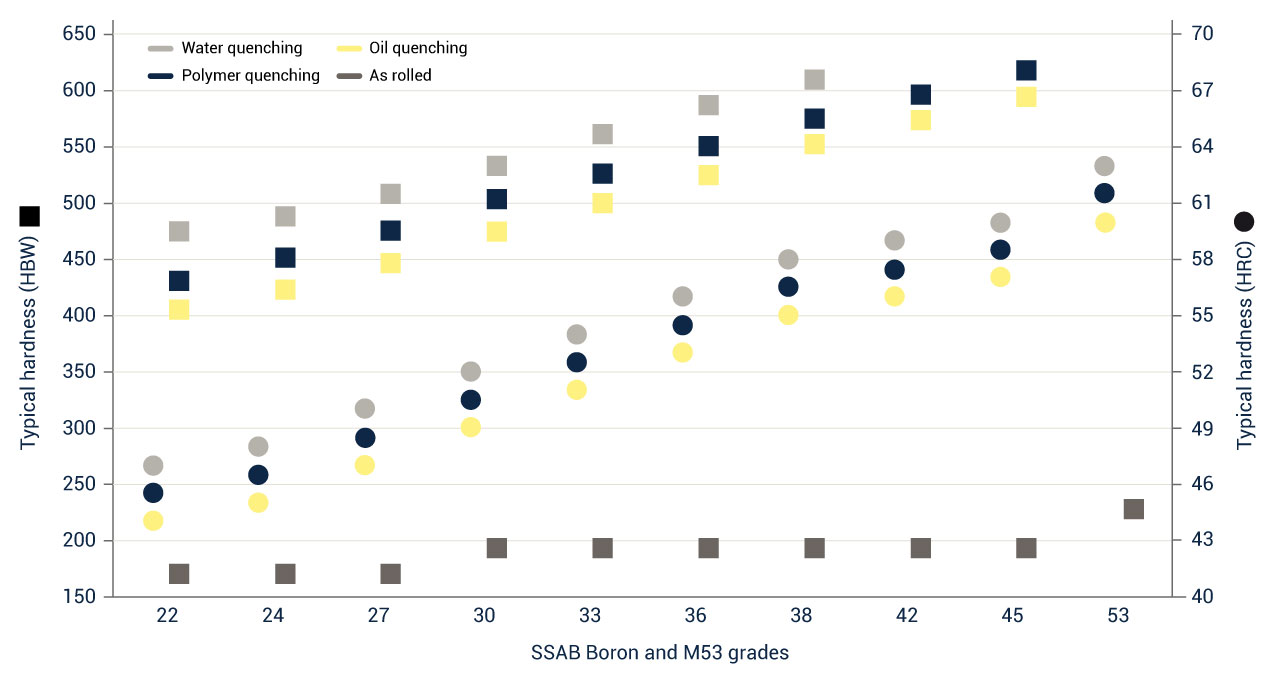

SSAB Boron and SSAB M53 steels come in a wide range of steel grades with carbon contents from 0.22–0.535 %. Available as hot rolled plate, hot rolled coil; slit coil and sheet; cold rolled coil, slit coil and sheet; tubes and sections. Hot rolled strip products are available in black, pickled and annealed condition. Availability is depended on grade. Tubes and sections are produced from hot and cold rolled base material.

Contact sales