- Products and Services

- Strenx

- Product offer and datasheets

- Strenx 1300 E/F

- Strenx 1100 product group

- Strenx 960 product group

- Strenx 900 product group

- Strenx 700 product group

- Strenx 650MC D/E

- Strenx 600MC D/E

- Strenx 100

- Strenx 100 XF

- Strenx 110 XF

- Strenx Tube product group

- Strenx weathering product group

- Strenx Section 650MC

- Strenx Section 700MC

- Strenx Section 900MC

- Strenx for lifting

- Strenx for trailers

- Strenx for agriculture

- Sustainable structural steel

- StrenxCalc

- Customer cases

- Strenx guarantee

- My Inner Strenx

- Strenx Certified Fabricators

- Downloads

- Contact sales

- Contact tech support

- SSAB Docol

- All automotive steel grades

- Martensitic steel

- Complex phase steel

- Dual phase steel

- Dual phase with high formability steel

- High strength low alloy steel

- High edge ductility steel

- Ferritic Bainitic steel

- Press hardening steel

- Tubes

- Coating

- Custom AHSS for automotive OEMs

- Advanced high strength steel

- Ultra high strength steel

- Contact sales

- Contact tech support

- SSAB Zero products

Hardness

Discover how hard Hardox® wear plate works to provide superior wear resistance during the entire service life of a wear plate.

Built to take a beating

Rocks, sand, coal, minerals, scrap metal and other hostile materials find it hard to make a lasting impression on Hardox® wear plates. With its combination of high hardness, strength and toughness, Hardox® steel has proven itself as the abrasion-resistant steel of choice for extending the service life of equipment, parts and structures in the most challenging environments.

A lifetime of savings

Extreme wear resistance is also a strategic business factor. When you extend the service life of your equipment two, five or even ten or more times, you can watch your productivity — and your savings — grow.

The hard facts

Hardness is the property that provides excellent wear protection during the entire service life of a Hardox® wear plate.

How hard is hard?

Whatever you call this property — yield strength, tensile strength or hardness — we know that it keeps a structure in shape without the structure becoming plastically deformed. Watch how we test Hardox® steel before it digs into the ground.

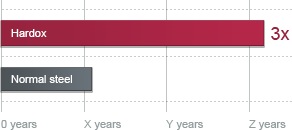

Hardox® wear plate vs mild steel

How hard is hard?

Toughness

Customer cases

Read about our customers' success using Hardox®.

Find out more