Excellent working height and outreach

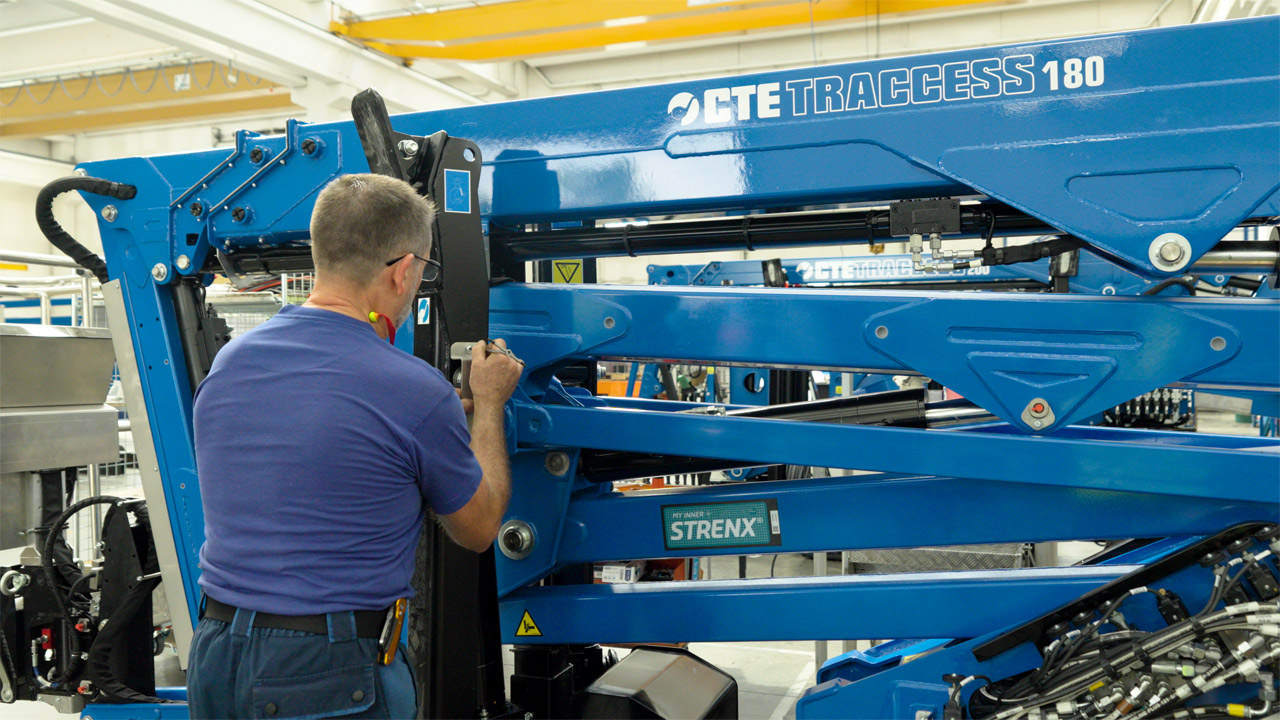

The company's latest solution to this challenge is its CTE ZETA 24 J, a truck-mounted platform, crafted from Strenx® 700 MC steel and Strenx® 960 CR steel.

“The ZETA 24 J has been developed with one thing in mind only – to have the maximum performance on a narrow jacking configuration. It means that we don't have extendable outriggers anymore, only outriggers straight down,” says Roberto Berritta.

ZETA 24 J is developed and designed for the rental industry, and to offer the operator great versatility as well as excellent working height and outreach. Simply explained, it offers 24 meters of working height, 12 meters of outreach and a basket capacity of 250 kg.

“The main advantage for the operator and rental companies is that it is very easy to use. Then we have been able to put the maximum performances on the upper structure by up to 10 meters and over by almost 12 meters. That's an amazing performance even for a unit with extendable outriggers. We have designed a machine that does the same performances on narrow jackets as with extendable outriggers,” says Roberto Berritta.

Building lighter platforms is the key

These benefits to the end customers are made possible by the fact that SSAB's crafted Strenx® 700 MC and Strenx® 960 CR steel is used in all of the truck-mounted platforms' structural parts.

“To achieve all this we needed the thinnest and strongest steel possible – like the Strenx 960. Very thin, 1.5 mm, with shapes of the boom and the pantagraph, that were allowing for the same resistance, the same structural integrity and the same capability of resisting buckling. All these things together with a steel that still can be welded and guarantee a long life cycle. At least 100,000 cycles over 10 years of operation,” says Roberto Berritta.

The result of using 1.5 mm Strenx® 700 MC and Strenx® 960 CR steel is 25 percent reduced weight in the upper structure of the truck-mounted platform.

“When we started this work of improvement in order to make our machines lighter we were using 3-4 mm thick Strenx 700 steel. Then we slowly used thinner and thinner steel, and now we use 1.5 mm steel. The upper structure before weighed around 1,250 kilo and today weighs around 1,000 kilo and has even better performance,” says Roberto Berritta.