SSAB’s transformation of its Nordic production system is the first true steelmaking transformation in centuries. All five blast furnaces in Sweden and in Finland will be replaced by more flexible and cost-efficient mini-mills that run on electricity.

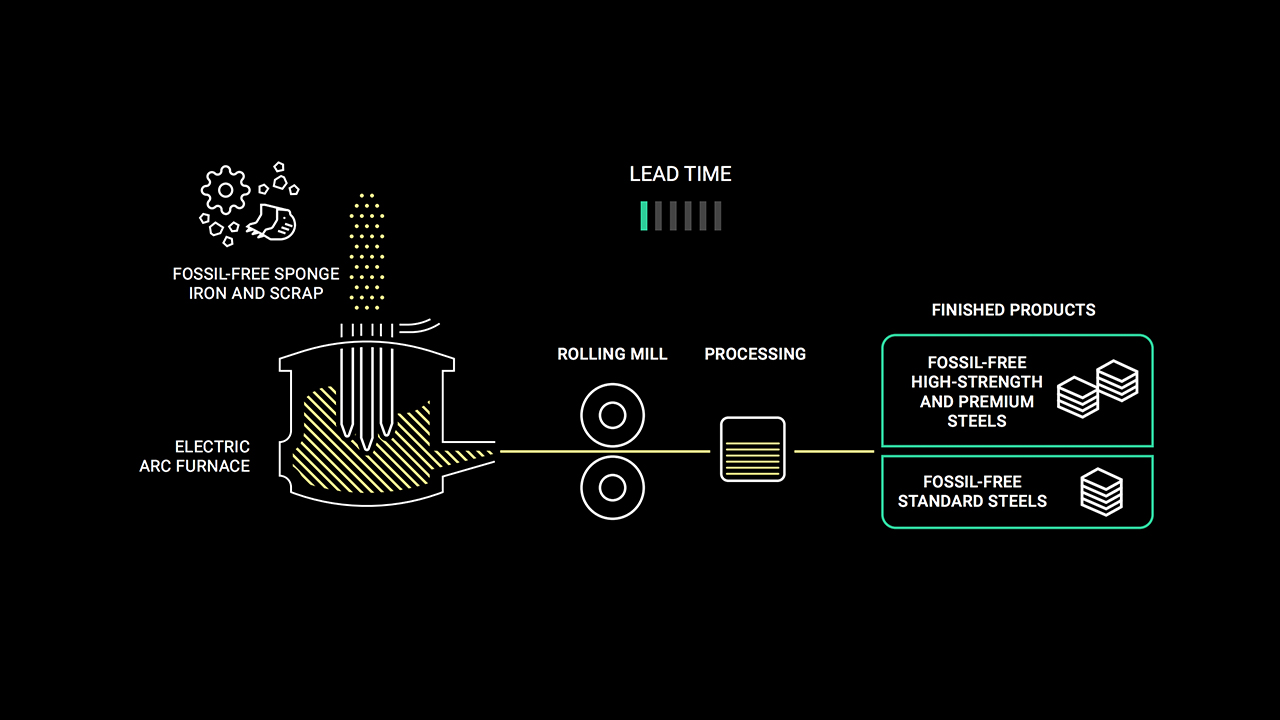

Luleå in Sweden and Raahe in Finland will get new mini-mills that are at the heart of the new Nordic production system. These mills are integrated steel production facilities with the capacity of carrying out all steps of steelmaking from melting fossil-free sponge iron and scrap to rolling products.

The new mills will typically have an electric arc furnace, a ladle furnace or vacuum furnace for precision control of chemistry, a strip or billet continuous caster for converting molten steel to solid form, a reheat furnace and a rolling mill.

In June 2023, we decided to invest in an electric arc furnace in Oxelösund. And in April 2024, the investment decision was made for the transformation of the Luleå site. The third step planned is for the transformation of Raahe, Finland. The Raahe project timing will depend on SSAB’s financing and execution capacity, as well as the learnings from the Luleå project.