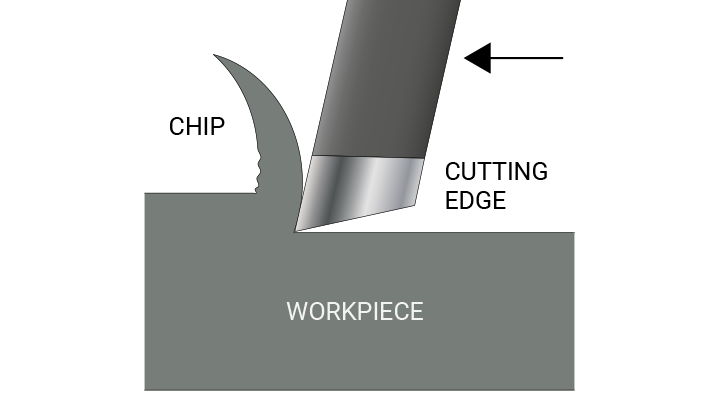

1. What is machining?

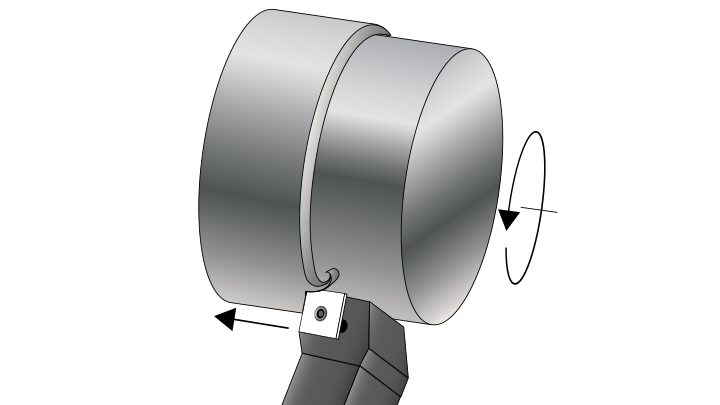

2. What are the various machining operations?

3. Is it possible to machine high-strength steels?

4. What is CNC machining?

5. Where can I find cutting data for machining SSAB steel?

Cutting data for machining is available in SSAB’s machining brochures.

6. What is material hardness?

7. What is machinability?

8. How does material hardness affect machinability?

9. Can I use a column or radial drilling machine when drilling into wear plates?

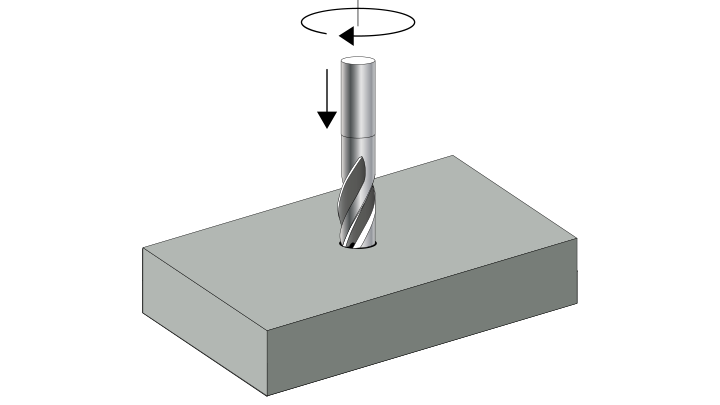

10. What is drilling?

11. Can I use a high-speed steel drill to drill into wear plates?

It is possible to drill into very hard steel, like wear plates. For Hardox grades up to Hardox 500, you can drill single holes into a stationary drilling machine with high-speed steel drill/you can use a stationary drilling machine with a high-speed drill to drill single holes together with low cutting speed and a lot of cooling. For even harder steels, a solid carbide drill or a carbide tipped drill must be used.

12. Can I use a hand drilling machine when drilling into wear plates?

13. How can I drill with indexable inserts into hardened steel?

14. How do I use a coated solid carbide drill for wear plates?

15. How can I countersink pre-drilled holes?

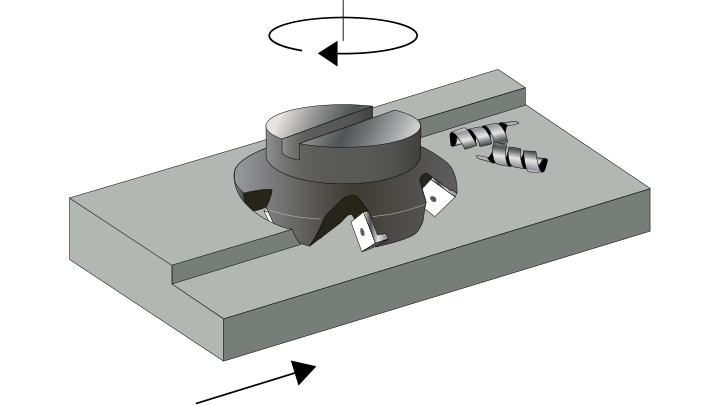

16. How can I countersink if not using an appropriate countersinking tool?

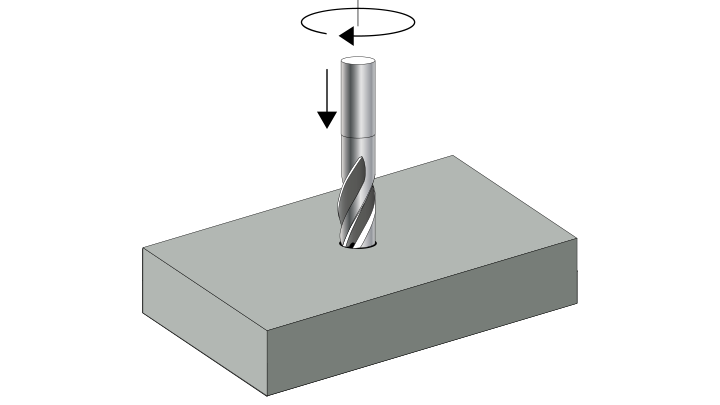

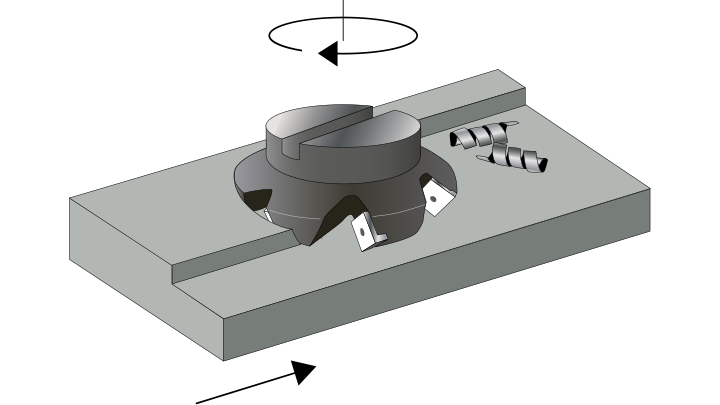

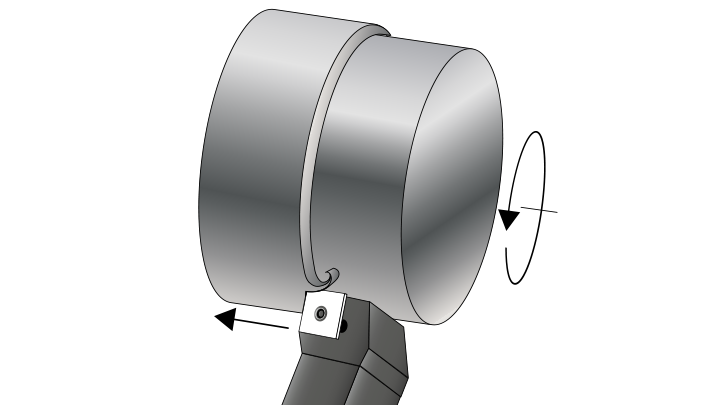

17. What is milling?

Milling is a cutting process producing chips. Cutting inserts are rigidly mounted on a rotating tool (milling body). The milling body cutting edges can have various shapes. The workpiece is clamped onto a table. Both the table and the tool can be moved independently in one or more spatial dimensions. The movements can be controlled manually or by a computer program (CNC).

18. How can I mill wear plates?

The machine must be stable, and the workpiece must be well clamped. Use only a milling body equipped with carbide inserts for wear plates harder than 400 HBW. Use cutting feed provided by the tool manufacturer. It is worth trying a gradual increase in cutting speed to save time. Start from a low cutting speed.

19. What is the difference between roughing and finishing?

The information in this report is only applicable to SSAB’s products and should not be applied to any other products than original SSAB products.

This report provides general results and recommendations for SSAB steel products. This report is subject to SSAB’s Terms of Use. It shall be the user's responsibility to verify that the information contained herein is correct and is suitable to be used for the particular purpose and application of the user. The report is intended to be used by professional users only who possess adequate expertise, qualification and knowledge for the safe and correct use of the results and recommendations in this report. This report is provided “as is”. The use of the report is at user’s own discretion and risk and that users will be solely responsible for any use of this report. SSAB disclaims any liability for the content or potential errors of this report, including but not limited to warranties and condition of merchantability or fitness for a particular purpose or suitability for individual applications. SSAB shall not be liable for any kind of direct or indirect damages and/or costs related to or arising therefrom, whether special, incidental, consequential or directly or indirectly related to the use of, or the inability to use, the report or the content, information or results included therein.