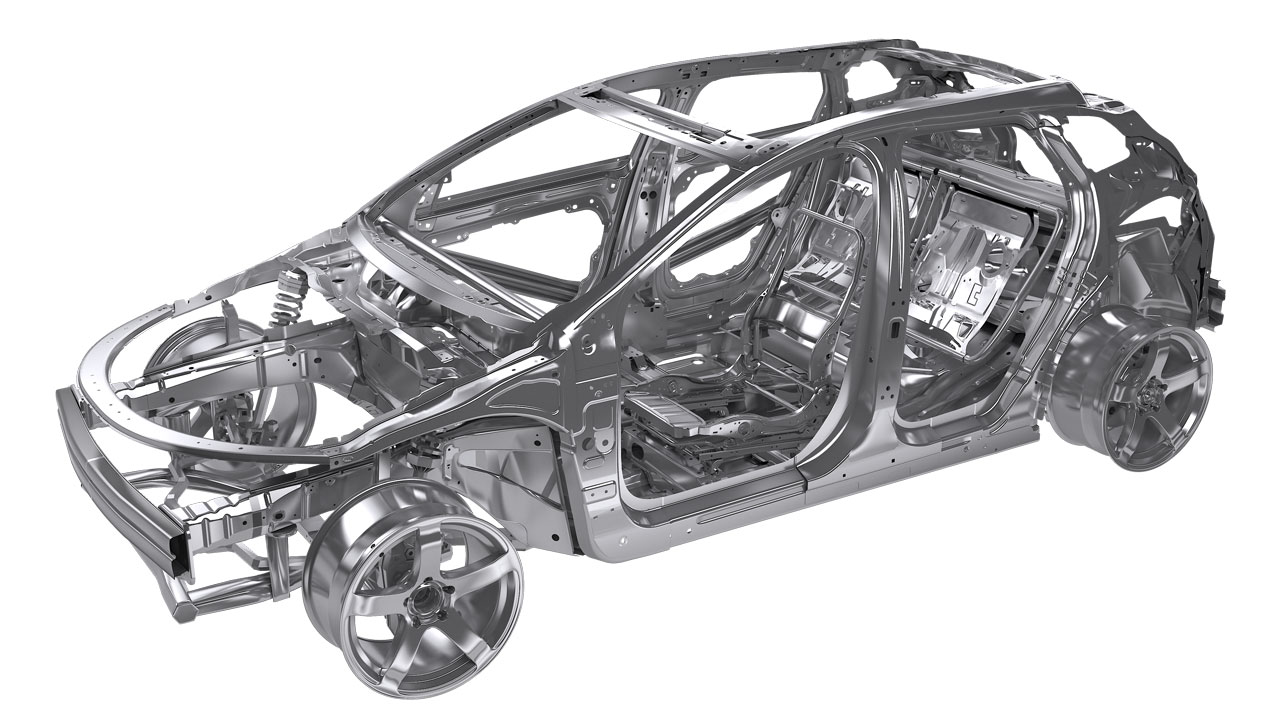

Dual phase (DP) steel: excellent ductility and energy absorption

Dual phase automotive steels have an excellent balance of ductility, high tensile strengths, easy cold formability, and very good crash energy-absorption. Its high early-stage strain hardening (n-value) makes DP steel resistant to local necking due to strain redistribution — providing highly uniform elongation. Dual phase steel’s low yield-to-tensile-strength ratio creates high global formability for deep-drawing and high-stretching capacities — all with good weldability.