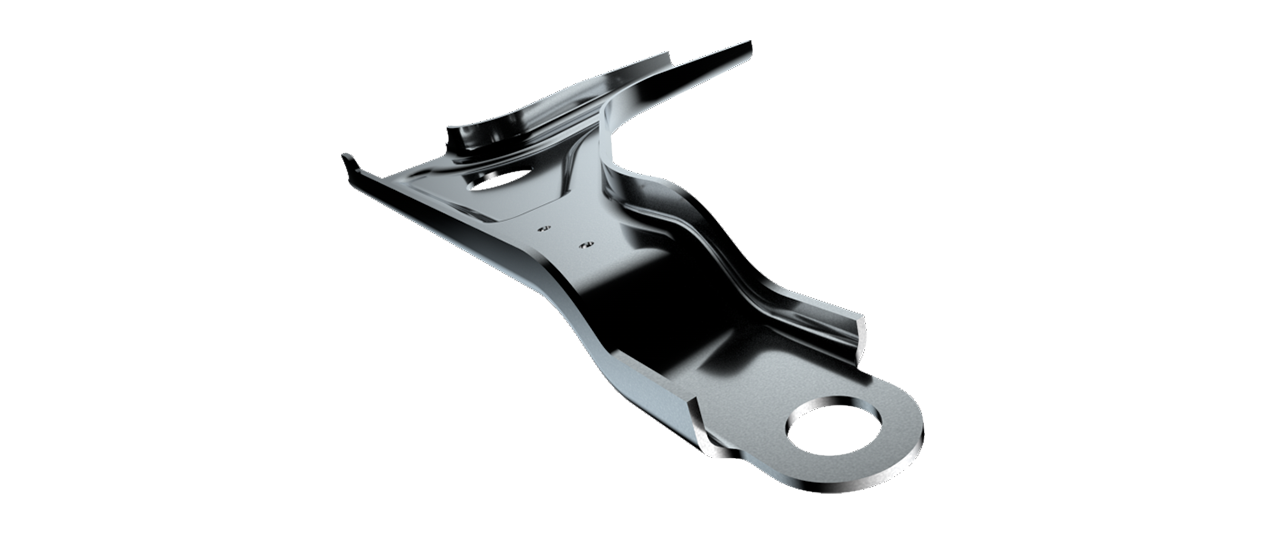

Complex phase (CP) steels for the highest hole expansion ratios

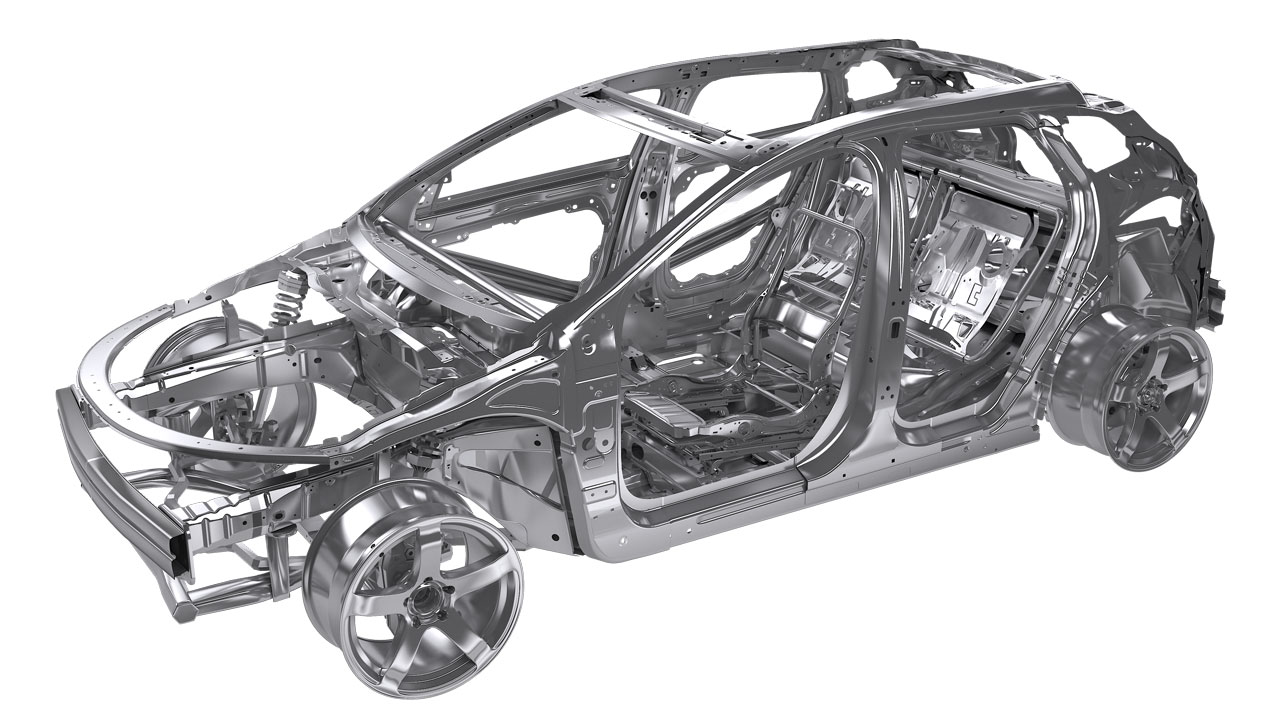

Complex phase steels have the highest — up to 100% — hole expansion ratios available from advanced high strength steels. Their high HER values provide excellent cold-forming properties for punched and stretched edges/flanges, as well as deep-drawn shapes. CP steels’ superior yield strengths are used for high crash-energy absorption, while their elevated UTS levels enable thinner walls for significant automobile weight reductions.