1. What does designing with high-strength steel involve?

Designing with high-strength steel involves selecting the appropriate steel grade and optimizing the material properties and design geometry to achieve better performance and lower weight. Well-designed high-strength steel structures can withstand higher stresses than comparable mild steel structures, resulting in increased strength and durability.

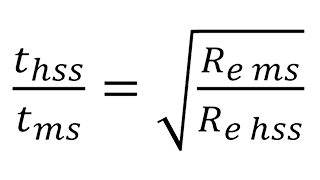

2. How is the design "rule of thumb" used?

The design “rule of thumb” considers stress levels of a plate in bending. Mostly, it is conservative for other components with respect to elastic load carrying capability. Be aware that the stiffness is reduced when working solely with thickness reduction according to the rule of thumb. Stability and fatigue are phenomena that the rule of thumb does not consider, and these need to be addressed specifically. It is important to note that the rule of thumb is not applicable for all components, particularly those subjected to deformation limits, stability issues and fatigue loads.

where:

tms = thickness of the mild steel

Re ms = yield strength of the mild steel

Re hss = yield strength of the high-strength steel

|

Current |

Upgrade Yield strength (MPa) |

Thickness reduction |

| 355 | 700 | 29% |

| 355 | 960 | 39% |

| 700 | 960 | 15% |

| 960 | 1100 | 7% |

| 960 | 1300 | 16% |

| 1100 | 1300 | 8% |

3. What design changes need to be made when upgrading to a steel with higher performance?

When upgrading to a steel with higher performance, the stresses in the structure may increase, which can reduce the fatigue life if not addressed properly. Welded joints are often the weakest link and removing them in favor of forming operations using larger plates can increase fatigue life. Geometrical stress raisers, such as holes, should also be moved to lower stressed areas.

Furthermore, the reduction in stiffness due to thinner plates can be compensated with minor changes in geometry. Also, depending on the slenderness of the structure, stability issues such as buckling may need to be addressed specifically. To effectively design with higher performance steel, it is important to consider the specific requirements of the application and the potential effects of increased stresses.

By optimizing the geometry, reducing stress raisers, and addressing stability concerns, high-strength steel can be effectively utilized to achieve the required performance and durability, while minimizing potential issues that may arise.

4. What are the design challenges when reducing the structure thickness?

Since the modulus of elasticity for steel is the same irrespective of grade, the stiffness will be reduced when the thickness of the structure is reduced. Additionally, structural stability such as local, overall, and torsional buckling may become critical. Furthermore, the stresses in a well-designed high-strength steel structure may increase, which can reduce fatigue life, with welded joints often being the weakest link.

5. Which material properties of high-strength steel are used for lightweight structural solutions?

The higher yield and ultimate tensile stresses of high-strength steel make it a useful material for lightweight structural solutions. Additionally, the increased hardness of high-strength steel is beneficial for wear applications.

To take advantage of the material properties of high-strength steel for lightweight structural solutions, choose a steel with high yield strength when strength is the primary concern. When high energy absorption is required, choose a steel with high tensile strength. For wear applications, choose a wear plate with high hardness.

6. Which factors are important to consider in designing with thinner material?

Designing with thinner material presents several challenges.

First, reducing the thickness of a structure will decrease its stiffness and overall structural stability, making it more susceptible to buckling and deformation.

Second, fatigue life, especially of welded joints, becomes a significant concern due to the higher stresses that are often present in thinner materials.

Third, additional factors such as toughness in cold environments, energy absorption, and wear resistance must be considered. Finally, manufacturing parameters might need adjusting.

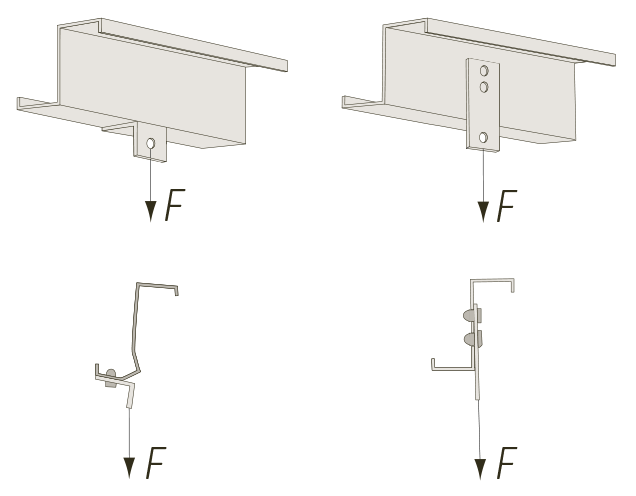

7. What is the plate action vs. skin action?

Plate action refers to the behavior of a plate when subjected to a force perpendicular to its surface, while skin action describes the behavior of a plate when the force acts in the plane of the plate. Plate action leads to bending stresses that vary across the cross section of the plate, while skin action generates membrane stresses that are uniform across the cross section. Skin action is more effective in utilizing the material strength compared to plate action and is often preferred for lightweight designs.

8. Which design standards are used for designing and dimensioning with high-strength steels?

The standards used for designing and dimensioning with high-strength steels depend on the specific application. While there is currently no general standard for high-strength steel design, many of the common standards and norms have been validated for use with high-strength steels. Designers can typically find application-specific standards for high-strength steel design by consulting machine directives and structural standards.

For example, the European Union Machinery Directive provides requirements for the design and construction of machinery, including the use of materials such as high-strength steel. Additionally, there are various structural standards such as Eurocode and AISC that provide guidelines for the design of structures using high-strength steel. It is important for designers to carefully consider the relevant standards and norms for their specific application to ensure legitimacy as well as safe and effective use of high-strength steels.

9. What are the consequences of stresses above the yield stress of the material?

Plastic deformations. Depending on the extent of the material volume with stresses above the yield stress, the structure might redistribute the stresses over a larger volume and thereby maintain the structural integrity. If a larger part of the structure experiences stresses above the yield stress, it can lead to distorted structural elements or, in the worst case, loss of structural integrity, and thus failure.

10. Why is it important to keep everyday stresses lower than the yield stress of the material?

Assuming that the structure is supposed to work similarly from day to day, if the everyday stresses exceeds the yield stress of the material, the structure will gradually deteriorate from plastic deformations, and finally be destroyed or lose its function. Over time, fatigue will most probably occur as well.

Measures to keep everyday stresses lower than the yield stress of the material may include proper design, inspections, maintenance, load management, field data reports, and material testing.

- Proper design and choice of material can help to ensure that the stresses in the structure are kept well below the yield stress of the material.

- Regular inspections can identify any areas of the structure where stresses may be building up beyond safe limits. This allows corrective action to be taken before significant damage occurs.

- Regular maintenance can identify and address issues, such as corrosion or wear, that may contribute to stress buildup.

- Careful management of the loads that the structure is exposed to can help to keep stresses within safe limits. This may involve limiting the weight of loads, distributing loads evenly across the structure, or using support structures to reduce stress concentrations.

- Collection of field data by following up a set of products.

Regular testing of the material can identify any changes in its properties that may affect its ability to withstand stress. This can help to prevent failures due to changes in material properties over time

11. What is the meaning of "allowable" stress levels in a structure?

"Allowable" stress levels refer to the maximum stress that can be permitted in a structure under a specific service condition. The value of the allowable stress depends on the frequency of the service condition, the probability of failure, and the consequences of failure for that service condition.

To ensure that stress levels in the structure remain within the allowable limits and prevent potential failures, the following measures can be taken:

- Proper design and material selection should ensure that the maximum stress caused by expected loads remains within the allowable stress limit.

- Regular inspections can identify any signs of stress concentration or deformation that could lead to failure. This allows corrective action to be taken before the stress levels exceed the allowable limit.

- Proper management of the loads applied to the structure can help to maintain stress levels within the allowable limits. This may include limiting the weight of the loads or evenly distributing them across the structure.

- Regular maintenance can help identify and address any issues, such as corrosion, wear and tear, that may contribute to stress buildup or other structural damage.

- Collection of field data by following up on a set of products is helpful in finding indications of high stresses.

Testing of the structure can determine if the stress levels are within the allowable limit and can also identify any changes in the structure that could lead to stress concentration and failure.

12. What decides how high stresses are allowed in a structure?

In many applications, allowable stress levels are determined by industry standards or codes. However, if no standard or code is applicable, proper safety factors must be applied to determine the allowable stress. The allowable stress is typically set in relation to the yield stress of the material for static loads, but it can also be more complex, taking factors such as stability and fatigue into consideration.

If no standard or code is applicable, the acceptable consequences for a failure under certain service conditions need to be evaluated. An allowable stress is decided depending on the service condition frequency, its probability, and the consequences of a failure. The allowable stress is usually set in relation to the yield stress of the material. In addition, the allowable stress can, for instance depend, on fatigue and/or stability. E.g., for something that happens every day, the structure should probably need to be unaffected, but for an accident that happens once in every ten years it might be enough that the structure just doesn´t fall apart. The allowable stresses for these two cases are therefore different.

13. How can undermatching welding filler material be used in a steel structure?

Welds in steel structures typically have a larger cross-sectional area than the corresponding base material, leading to lower stress within the weld compared to the base material. This means that undermatching welds, which use a filler material that has a lower strength than the base material, can still be acceptable.

Additionally, when the weld joint is stressed, a three-dimensional redistribution of the stresses due to the plasticity of the joint can occur, often not affecting the total design. Furthermore, the allowable stress with respect to fatigue is lower than the yield strength and, in these cases, undermatching weld material is acceptable.

14. How can the allowable stress for a welded joint be calculated?

In the case of static stress, the cross-sectional size of the weld and the strength of the weld material are the main factors to consider. An appropriate safety factor against yield is also taken into account to ensure that the joint can withstand the expected load without failing.

In the case of static stress, the allowable stress can be estimated based on the cross-sectional size of the weld, the strength of the weld material, and an appropriate safety factor against yield.

However, in the case of the fatigue of loaded weld joints, the calculations regarding the allowable fatigue stress become more complicated. A variety of methods can be used to calculate the allowable stress for a welded joint , depending on the specific application and loading conditions.

For the fatigue of loaded weld joints, the allowable stress is determined by considering factors such as the number of cycles, the loading range and the type of loading.

To ensure accurate calculations and safe design, it is recommended to use relevant standards and guidelines, such as the SSAB Design Handbook, which provide comprehensive information on the design and analysis of welded structures. The handbook includes information on static and fatigue stress calculations, as well as other important considerations such as weld quality, joint design, and material selection.

15. How calculate the allowable stress for a bolted joint?

To ensure proper joint behavior in a bolted joint, the pre-tension of the joint must be maintained during loading. In the static case, an F-d (Force-displacement) -graph is typically used to calculate the stiffness of the bolt and clamped parts and establish force equilibrium between them. It is desirable to achieve a pre-tension stress of around 70-90% of the yield stress of the bolt. Various factors such as hole bearing failure, material failure, and edge failure must also be considered, depending on the joint type.

In the dynamic case, a fatigue evaluation of the bolted joint is necessary. Suitable fatigue resistance values for bolts can be found in literature. External loads do not equate to the load experienced by the bolt in a well-designed joint. The load range in the bolt from external loads can be understood by studying the F-d (Force-displacement) -graph. This load range, together with the desired fatigue life, establishes the allowable stress or force in the bolted joint. An assessment of the hole should also be performed

16. What needs to be considered when designing a bolted joint?

Designing a bolted joint requires consideration of several factors. First, the strength and stiffness of the clamped parts must be determined to ensure that the joint can withstand the expected loads.

The strength and stiffness of the bolt must also be considered to ensure that it does not fail under load. The choice of bolt material and diameter should be based on the expected loads, environmental conditions, and other factors such as corrosion resistance.

The length of the bolt should be chosen to provide adequate clamping force and avoid excessive stress concentrations in the clamped parts, it's essential to ensure that the bolt is less stiff than the clamped parts. The choice of bolt tightening method should also be considered, as this can affect the preload and the distribution of forces in the joint.

17. Can my FEA software calculate the allowable stress for fatigue in a welded joint?

No, FEA software is a powerful tool for simulating mechanical behavior, but it cannot calculate the allowable fatigue stress in welded joints.

Although some FEA software packages have fatigue modules, these are typically designed for evaluating castings and parent material rather than welded joints. To evaluate fatigue in welded joints, there are several commonly used methods available, including the nominal stress method, the hot spot stress method, and the effective notch stress method. The two latter involve the use of FEA to determine the fatigue life of the welded joint.

However, these methods require expertise and may not be reliable without proper calibration and validation.

18. What is strain rate?

Strain rate is a measure of how quickly a material deforms over time. It is expressed as ε ̇=dε/dt, where ε ̇ represents the strain rate, and dε/dt is the derivative of the strain with respect to time. Strain rate is a critical factor in many applications, such as material testing, forming processes, and impact loading.

Measuring strain rate typically requires specialized equipment, such as a strain rate sensor or high-speed camera, depending on the application and required accuracy. It is important to understand the effect of strain rate on material behavior since some materials exhibit different properties at different strain rates. This effect can be particularly important in applications where the material will be subjected to high strain rates, such as in impact loading or crash testing.

19. What is the relationship between strain rate and the mechanical properties and deformation behavior of materials?

The strain rate at which a material is deformed can have a significant effect on its mechanical properties and deformation behavior. In general, increasing strain rates can result in higher yield and tensile strengths, as well as increased stiffness and hardness. This is particularly important in applications involving high strain rates, such as car collisions, loading of dumper bodies and ballistic impacts, where rapid deformation occurs. For example, in high-strength steel, local strain rates of approximately 500 s-1 during a car collision can lead to a yield stress increase of approximately 100 MPa.

20. What is important in designing with FEA?

Finite Element Analysis (FEA) is a powerful tool for analyzing the behavior of structures and components under different loading conditions. However, FEA is subject to uncertainties, and its accuracy and reliability depend on the quality of input data, including loads, material properties, and geometric design.

To ensure reliable results, it is important to validate FEA results through experimental testing whenever possible. When relevant load data is not available, a relative analysis can be performed by comparing an existing design with known performance to a similar analysis of an upgraded design. This can help assess the impact of the upgrade on performance in relative terms.

When designing with FEA, it is important to carefully consider input data and validate the results through experimental testing whenever possible. It is also crucial to understand the assumptions and limitations of FEA and the effects of modeling choices such as element size and boundary conditions. The FEA model should be calibrated against experimental results to ensure its accuracy and reliability.

Additionally, FEA can be used as a tool to optimize structures and components for optimal performance under different loading conditions.

The information in this report is only applicable to SSAB’s products and should not be applied to any other products than original SSAB products.

This report provides general results and recommendations for SSAB steel products. This report is subject to SSAB’s Terms of Use. It shall be the user's responsibility to verify that the information contained herein is correct and is suitable to be used for the particular purpose and application of the user. The report is intended to be used by professional users only who possess adequate expertise, qualification and knowledge for the safe and correct use of the results and recommendations in this report. This report is provided “as is”. The use of the report is at user’s own discretion and risk and that users will be solely responsible for any use of this report. SSAB disclaims any liability for the content or potential errors of this report, including but not limited to warranties and condition of merchantability or fitness for a particular purpose or suitability for individual applications. SSAB shall not be liable for any kind of direct or indirect damages and/or costs related to or arising therefrom, whether special, incidental, consequential or directly or indirectly related to the use of, or the inability to use, the report or the content, information or results included therein.