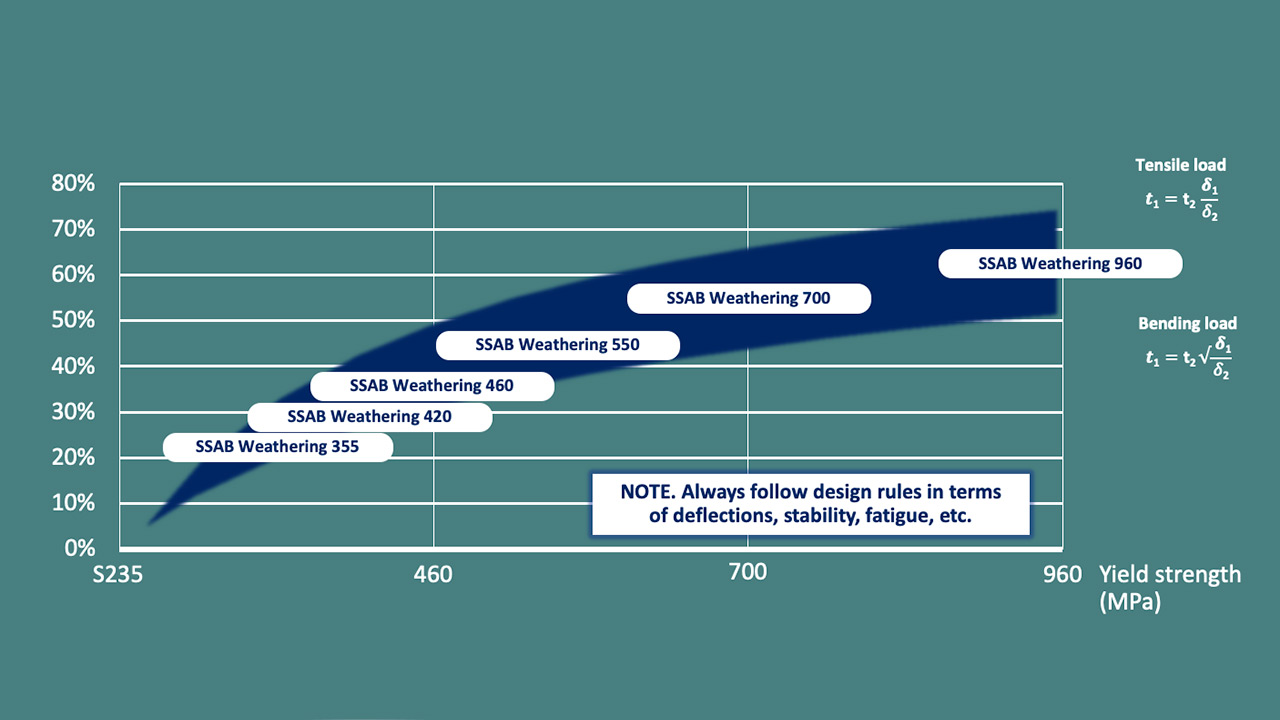

SSAB has developed a wide range of weathering steel in yield strength levels up to 960 MPa, which enable lower steel weight of the structures even with typical corrosion allowances of weathering steel. This means that corrosion allowances needed for weathering steel don’t necessarily increase the weight, and when combined with high-strength grades the steel weight and related embodied carbon can be lowered, too. This opens up new application possibilities especially in the thin range of 3-8 mm.

Recently, some high-strength weathering grades have been also standardized in Europe under harmonized products standards EN 10025-5:2019 and EN 10219-3:2020 for flat and tube products, and the steel structures made out of these grades can be also CE-marked by the customer. Consequently, interest on the European market for this unique combination of weathering properties connected to high strength has been steadily rising.

Use better steel – go emissions-free with SSAB

SSAB is already one of the world’s most CO2-efficient steel companies. But thanks to our new approach to steel production, we are forging a path to introducing the market’s first fossil-free steel by 2026 and making our entire operations fossil-free 2045. SSAB Weathering steel will be part of this transformative offering.

SSAB’s Environmental Product Declarations (EPDs) comply with international standards, and they provide objective data highlighting the low carbon footprint of our products. SSAB Weathering steels are covered by EPDs as per ISO 14025:2006 and EN 15804:2012. And in the future, fossil-free weathering steel will be documented in an independently reviewed EPD and will conform to strict European and international standards. This assurance will cover all aspects of the steel production process, delivering a decarbonized value chain to our customers.

10 good reasons to use SSAB Weathering steel

Making the right material choices can have a huge impact on the sustainability profile of a steel structure. Here are 10 good reasons to use SSAB Weathering, with regard to product performance, environment and costs:

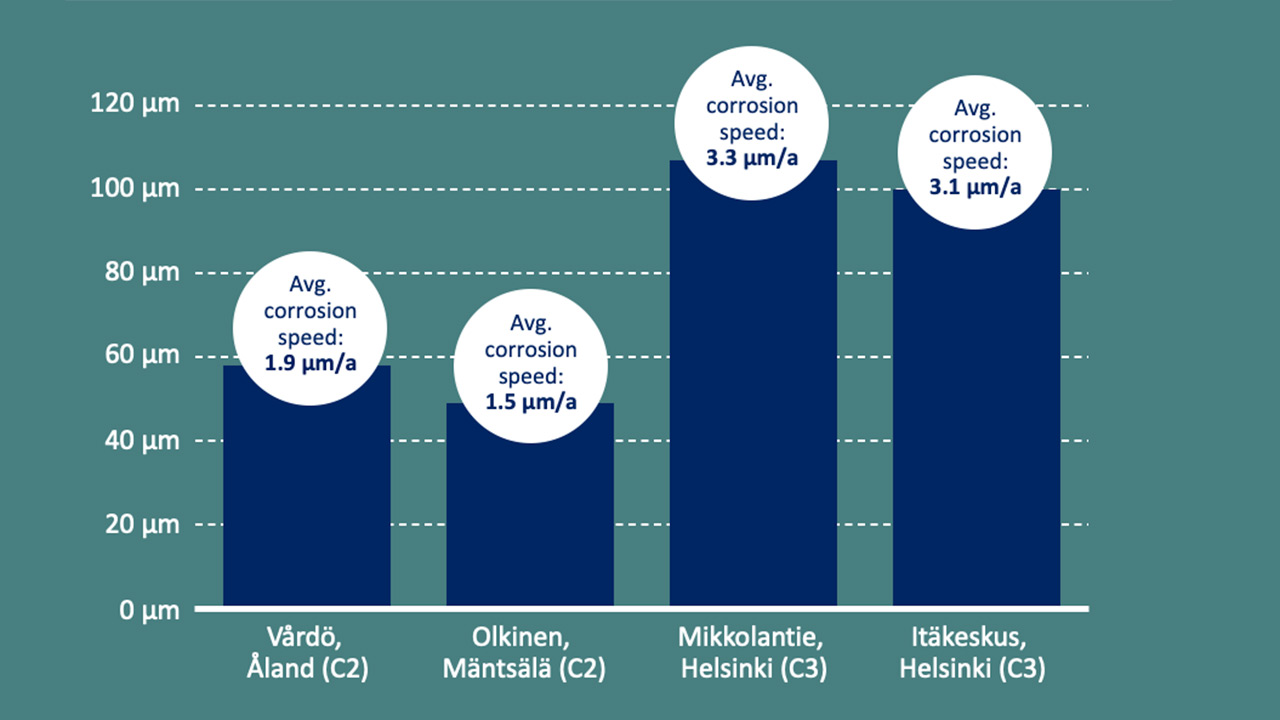

- Comparable service life to coated carbon steel, 40-100+ years in C3 when applied properly

- Ready to use - no need for galvanizing or painting means lower costs already in the construction phase

- When a painted surface for aesthetical reasons is required, doubling the interval for maintenance painting brings lower maintenance costs

- High-strength weathering products available in yield strengths 420, 460, 500, 550, 700 and even 960 MPa, enabling lower embodied carbon of lighter steel structures

- We already use the cleanest steelmaking practices and are leading the way towards fossil-free steel in industry

- No zinc run-off to the environment

- No coating damage in installation or transport

- No release of harmful chemicals related to painting and paint disposal

- No indirect costs of traffic delays or the closure of bridges and infrastructure due to maintenance

- Natural color and appearance