Docol® 700LA high strength low alloy

More about high strength low alloy steelDownload data sheet

Download data sheet

The Docol 700LA steels are high-strength low-alloy steels that offer consistent properties for modern, rapid production methods. The Docol 700LA steels are made for cold forming of stronger and lighter structures. Typical applications include components and parts in demanding load-bearing structures such as chassis. Docol HR700LA-UC can after agreement be adapted and delivered as dual certified with S700MC according to EN 10149-2.

Hot rolled / UC: thickness 2.00-6.00 mm, width up to 1600 mm.

Hot rolled / EG: thickness 2.00-3.00 mm, width up to 1360 mm.

Hot rolled / GI: thickness 2.00-4.00 mm, width up to 1400 mm.

Slit strip and cut to length sheets are available upon request.

Grade and coating specific restrictions on available dimensions may occur.

| Standard | Coating | Test direction |

Yield strength Rp0.2 (MPa) |

Tensile strength Rm (MPa) |

Elongation A80 1) (min %) |

Elongation A5 3) (min %) |

Min. inner bending radius for a 90° bend 4) | |

|---|---|---|---|---|---|---|---|---|

| Docol HR700LA | VDA 239-100 | UC, EG | L | 700 - 850 | 750 - 950 | 10 | 13 | 1.2 x t |

| VDA 239-100 | GI* | L | 700 - 850 | 750 - 950 | 10 2) | — | 1.2 x t |

The testing of mechanical properties of electro galvanized products is conducted without coating.

* Available upon request.

1) A80 value applies for thicknesses < 3.00 mm.

2) For GI coatings the minimum elongation value is reduced by 1 unit.

3) A5 value applies for thicknesses ≥ 3.00 mm.

4) In some cases tight bending radius may cause micro-cracking of the coating in the bend area. Where design permits, users are encouraged to employ larger radius.

| Coating | C (max %) |

Si (max %) |

Mn (max %) |

P (max %) |

S (max %) |

Al (%) |

Ti (max %) |

Nb (max %) |

Cu (max %) |

|

|---|---|---|---|---|---|---|---|---|---|---|

| Docol HR700LA | UC, EG, GI* | 0.12 | 0.60 | 2.10 | 0.030 | 0.025 | From 0.015 | 0.20 | 0.10 | 0.20 |

Hot rolled (UC, EG): Tolerances in accordance to EN 10051.

Hot-dip galvanized (GI): Tolerances in accordance to EN 10143.

Customized dimensional and shape tolerances are available upon request.

The metal coating options for Docol products include:

Hot-dip zinc coating (GI) consists almost entirely of zinc (>99%). It is lead free, resulting in a small zinc spangle size. The coating provides good corrosion protection.

Electrogalvanized coating (EG) is applied continuously by electro deposition. The coating consists of zinc (>99%). Electrogalvanized steel is characterized by its excellent surface quality and uniform coating thickness.

Grade specific availability of metal coatings for Docol products is given in the Mechanical properties table (Coating).

| Coating type | Coating class | Standard | Closest in EN standard, informative 1) | Coating mass per side, single spot test (g/m2) | Thickness per side informative (µm) |

|---|---|---|---|---|---|

| GI | 40/40 | VDA 239-100 | Z100 | 40 - 60 2) | 5.6 - 8.5 |

| GI | 50/50 | VDA 239-100 | — | 50 - 70 2) | 7.0 - 9.9 |

| GI | 60/60 | VDA 239-100 | Z140 | 60 - 90 | 8.5 - 12.7 |

| GI | 70/70 | VDA 239-100 | — | 70 - 100 | 9.9 - 14.1 |

| GI | 85/85 | VDA 239-100 | — | 85 - 115 | 12.0 - 16.2 |

| GI | 115/115 | VDA 239-100 | Z275 | 115 - 155 | 16.2 - 21.8 |

| EG | 12/12 | VDA 239-100 | ZE25/25 | 12 - 32 | 1.7 - 4.5 |

| EG | 18/18 | VDA 239-100 | — | 18 - 38 | 2.5 - 5.4 |

| EG | 29/29 | VDA 239-100 | ZE50/50 | 29 - 49 | 4.1 - 6.9 |

| EG | 47/47 | VDA 239-100 | ZE75/75 | 47 - 61 | 6.6 - 8.6 |

| EG | 50/50 | VDA 239-100 | — | 50 - 70 | 7.0 - 9.9 |

| EG | 53/53 | VDA 239-100 | — | 53 - 73 | 7.5 - 10.3 |

| EG | 60/60 | VDA 239-100 | — | 60 - 80 | 8.5 - 11.3 |

| EG | 65/65 | VDA 239-100 | ZE100/100 | 65 - 85 | 9.2 - 12.0 |

| EG | 70/70 | VDA 239-100 | — | 70 - 90 | 9.9 - 12.7 |

Docol metal coated products are available with surface quality for unexposed applications.

In addition to these coating masses, OEM specific coatings are available upon request.

1) For GI and GA the closest informative value refers to EN 10346. For EG to EN 10152.

2) For hot-dipped (GI, ZA, GA) hot rolled (HR) grades, the coating mass tolerance is increased to 30 g/m² by increasing the upper limit.

Uncoated (UC): available as oiled.

Hot-dip galvanized (GI): available as oiled and/or chemically passivated.

Electrogalvanized (EG): available as oiled and/or chemically passivated or phosphated.

All surface treatments are in accordance with RoHS directive (2011/65/EU) and do not contain Chromium VI (Cr6+). Surface treatments provide only temporary surface protection during transportation and storage. In order to avoid corrosion damages, care must be taken to keep the products dry during transportation and storage. If they become wet, they must be separated and situated so that they are dried quickly.

For information concerning fabrication, see SSAB´s brochures on www.ssab.com or consult Tech Support.

Appropriate health and safety precautions must be taken when bending, welding, cutting, grinding or otherwise working on the products.

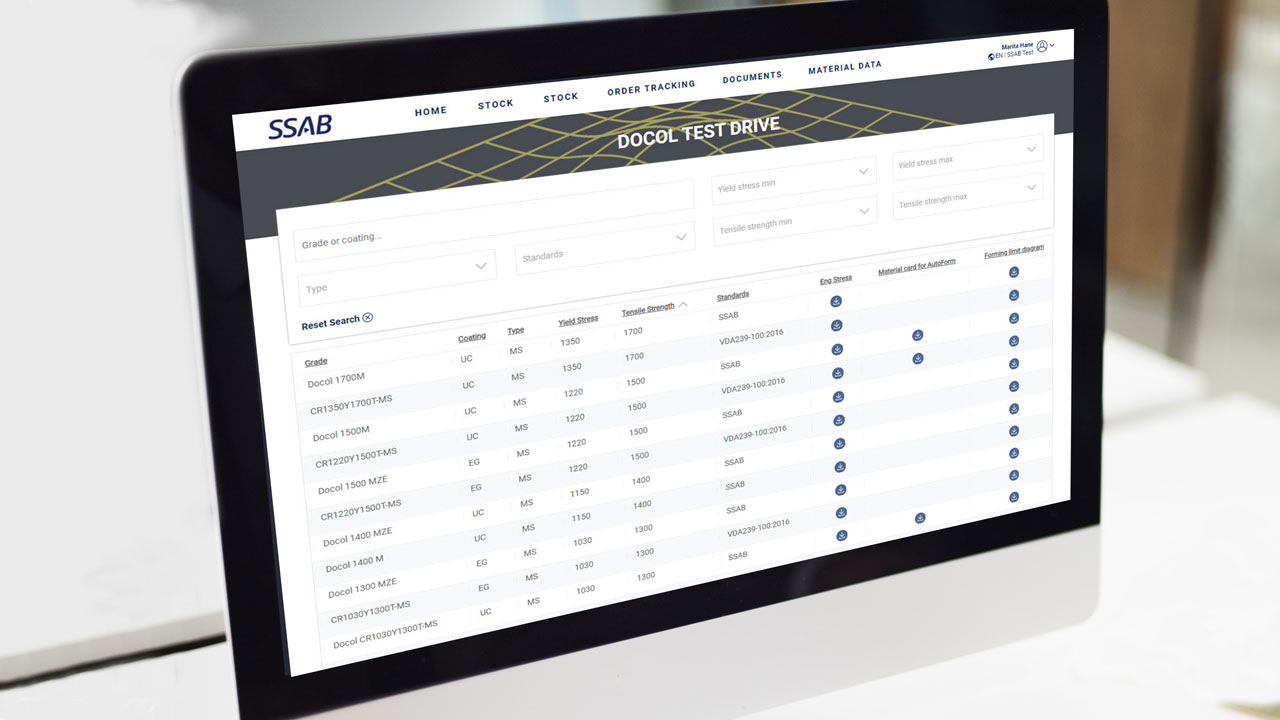

Want to discover unique automotive applications for AHSS materials? Try new production methods? Or create lighter components that can improve fuel efficiency, crash-worthiness and sustainability?

Docol® steel grades serve specific design purposes and are chosen by designers for a wide range of applications and used by OEMs and tier suppliers in millions of vehicles around the world.

Existing Docol® customers get 24/7 access to the forming data you need to help in your selection and simulation of automotive advanced high strength steels.