SSAB’s cold-formed steel sections are suitable for practically any kind of steel structure, whether for commercial or residential buildings, machines or appliances.

The accuracy of the cross-sectional form and good formability for high-strength material makes it possible to create long-lasting and light structures.

The steel in SSAB Domex Section meets or exceeds the requirements of EN 10149-2, EN 10025-2 or EN 10346 depending on selected product. SSAB Domex Sections' tolerances meet or exceed, when applicable, the requirements of EN 10162.

SSAB Domex Sections are available in various shapes and thicknesses. The maximum length of the sections is 21 meters, cut-to-length sections are available upon request.

Why choose cold-formed steel sections from SSAB

The benefits of our cold-formed sections include

- Highly precise shapes in almost any desired length and shape

- Attractive, smooth surface finish

- Uniform and consistent product, formed to tight tolerances

- High strength-to-weight ratio, lightweight product is easy to transport and erect

- Common jointing methods can be used (welding, bolting, adhesives, etc.)

- Recyclable at end of life

Explore our open steel section range

Available sections

- U-section

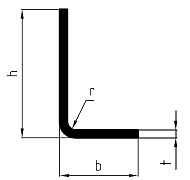

- Equal-angles section

- Unequal-angles section

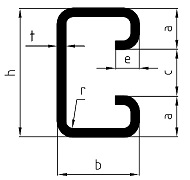

- C-section

- Lipped C-section

- Conveyor rail

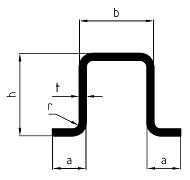

- Ω-section

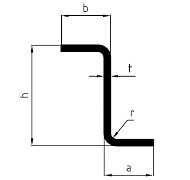

- Z-section

- Cable cover

See dimensional range below.

Need a custom piece?

Visit our tailor sections pageUp to standard – for your peace of mind

EN 10162

When you choose cold-formed steel sections from SSAB, you’re investing in materials that meet all the requirements of European standard EN 10162. Our cold-rolled structural steels meet all the technical delivery conditions under this standard, ensuring that you only get the highest quality product.

Introducing C section

SSAB manufactures high-quality C section steel by cold roll forming the steel into a C shape.

The C section consists of a wide web with two parallel flanges on the top and bottom of one side of the web and two lips.

Uses for C section steel

C channel steel often provides structural support in building construction that requires dimensional accuracy and high-quality steel. It is also used in automobiles, ships and other vehicles and to manufacture a variety of industrial, commercial and consumer products.

- Window and door frames, gates, fences

- Support for wooden beams

- Roof rafters

- Frames in cars, trucks and other vehicles

- Girts, studs, braces, joists and other structural components

- Conveyor rails

- Bridges and truss structures

- Power transmission towers, solar panel mounts

- Home appliances, metal furniture

C section sizes and grades

We provide C section steel in the standard grade S235J2C+N in a range of sizes. You can request other steel grades, plus custom lengths, punching and more.

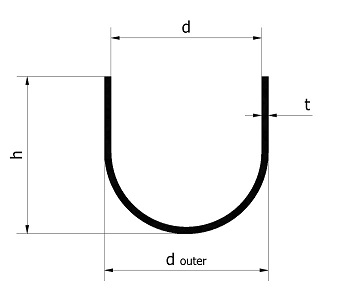

Introducing U channel steel

Cold-formed U channel steel is a highly accurate roll formed standard section

SSAB’s cold-formed U channel steel sections are suitable for replacing hot-rolled beams in many applications.

U channel steel sections include a very wide range of options for steel grades as well as steel dimensions. Dimensions exactly matching the application provide significant weight and cost savings. Each unit of weight saved by the U shaped steel channel will offer direct benefits in transportation and in the lighter weight of structures. Our cold-formed U channel steel sections are made according to EN 10162.

Cold-formed U channel steel sections are manufactured by roll forming using SSAB’s high-quality steels. It is mainly used in the construction, transportation and manufacturing industries where dimensional accuracy and high-quality steels are required.

SSAB’s cold-formed steel channels are suitable for replacing hot-rolled beams in many applications.

Replacing hot-rolled UNP beams with cold-formed U channel sections

Hot-rolled UNP beams can often be replaced with cold-formed U channel sections.

The benefits of using cold-formed U channel steel sections include

- The accuracy of the cross-sectional form and better straightness compared to the hot-rolled beam.

- U channel steel dimensions for cold-formed sections are almost unlimited.

- Cold-formed sections have a wide range of materials and the material can be selected depending on what is most appropriate to the application.

- Steel U channel sizes can be adjusted to customer needs, thus reducing scrap and the need for further processing.

This U-channel steel series has been developed with the same outside dimensions as hot-rolled UNP beams so that replacing hot-rolled beams is easier. The thickness is selected so that the cold-formed U-channel has the same bending strength, but it weighs less. Weight reduction has been achieved by using higher strength steel grade.

SSAB Domex sections

Dimensional range

Several shape possibilities and customer-specific lengths - More information from SSAB sales

SSAB Domex section 235

Steel grade: S235J2C+N EN 10025-2:2019

Band width (mm)

Wall thickness (mm)

Delivery length (m)

Band width (mm)

Wall thickness (mm)

Delivery length (m)

Band width (mm)

Wall thickness (mm)

Delivery length (m)

Band width (mm)

Wall thickness (mm)

Delivery length (m)

SSAB Domex section 500MC

Band width (mm)

Wall thickness (mm)

Delivery length (m)

SSAB Domex section 550MC

Band width (mm)

Wall thickness (mm)

Delivery length (m)

SSAB Domex section 320GD

Band width (mm)

Wall thickness (mm)

Delivery length (m)

SSAB Domex section 350GD

Band width (mm)

Wall thickness (mm)

Delivery length (m)

Stock sections

Dimensional range

Availability of stock sections, delivery length 6000 mm for all stock sections excluding cable covers 2500 mmU-Sections

Dimensions

Steel grade: S235J2C+N EN 10025-2:2019

* Available upon request

Equal Angles

Dimensions

Steel grade: S235J2C+N EN 10025-2:2019

* Available upon request

Unequal Angles

Dimensions

Steel grade: S235J2C+N EN 10025-2:2019

C Sections

Dimensions

Steel grade:S235J2C+N EN 10025-2:2019

* Optional steel grade: DC01 AM EN 10130:2006

Lipped C-Sections

Dimensions

Steel grade: S235J2C+N EN 10025-2:2019

Conveyor Rails

Dimensions

Steel grade: S350GD+Z275MAC EN 10346:2015

* Optional steel grade: S235J2C+N EN 10025-2:2019

Cable Cover

Dimensions

Delivery length 2500 mm

1) S320GD+Z275MAC EN 10346:2015

2) S350GD+Z275MAC EN 10346:2015

3) S235J2C+N EN 10025-2 (Hot dip galvanized)

* Shape rectangular

Z Sections (Manufacturing to order)

Dimensions

Steel grade:S235J2C+N EN 10025-2:2019

Hat Omega Sections (Manufacturing to order)

Dimensions

Steel grade:S235J2C+N EN 10025-2:2019